30% off on table spfa

Contemporary Setting

Wooden Material | 2 Year Waranteee

70% Flate

Wooden Stool

Gift Available | Free Delivery

30% Flate

Kabino Sideboard

3.5-inch (89 mm) | 4 Wide Box

eShop

Your advantages

- Energy-efficient water supply, thanks to a pump efficiency of up to 85.5 %

- Cost-efficient operation, thanks to the highest overall efficiency in this class with permanent magnet motor

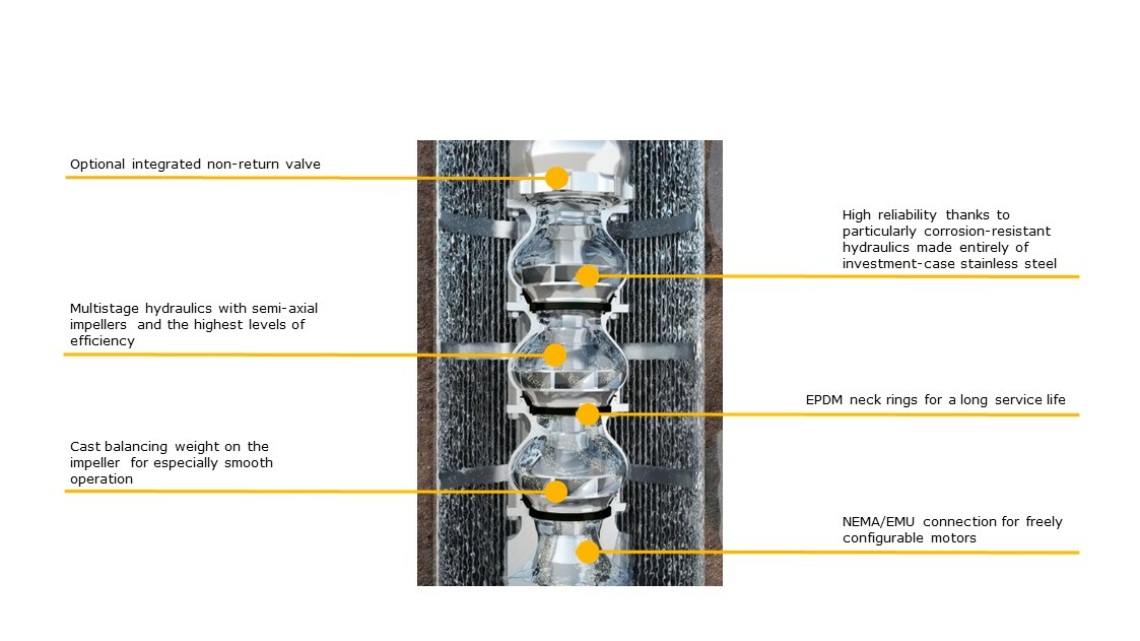

- High reliability thanks to particularly corrosion-resistant hydraulics made completely of 1.4408 grade stainless steel investment casting (AISI 316)

- High wear resistance: max. sand content of 150 g/m³

- ACS approval for use with drinking water

- Straightforward maintenance, easy installation and dismantling

Varying operating conditions

Changing water requirements and a fluctuating ground water level pose a major challenge for submersible pumps that operate optimally only at one duty point. With the Wilo-EFC the speed of the Wilo-Actun ZETOS-K10 can be continuously controlled. This allows flexible adaptation to all duty points and thus offers a solution for maximum energy efficiency and huge cost savings.

Universal operating sites

The Wilo-Actun ZETOS-K8 is suitable for universal use – in the agricultural, municipal water supply and industrial sectors. In addition, it is also suitable for dry well installation. Thanks to hard-wearing finely cast stainless steel, the Wilo-Actun ZETOS-K8 is also suitable for demanding applications. The maximum permissible sand content in the water is 150 g/m³.Which field of application is relevant to your needs?

Best in class. Robust. Universal.

1 - Field of application: Water supply and pressure boosting

Challenge: Flexible systems are needed to meet the fluctuating water consumption requirements of different types of buildings – such as schools, hospitals, stadiums and hotels. Solution: The Wilo-Actun ZETOS ensures a reliable water supply – even for high volumes. Wilo offers flexible systems for every installation location. The product is built into a pressure shroud for pressure boosting applications. This makes it overflow-proof, space-saving and quiet, as well as providing a reliable and convenient water supply.

2 - Field of application: Raw water intake

Challenge: With ever-increasing energy costs and an urgent need to reduce CO2 emissions, the municipal water management sector faces the challenge of providing a more energy-efficient drinking water supply. Solution:Using Wilo-Actun ZETOS high-efficiency pumps and motors unlocks significant financial and energy savings potential.

3 - Field of application: Clean water treatment

Challenge: Different water qualities need to be taken into account during the preparation of raw water. Some of these place high demands on the material characteristics of borehole pumps. Solution:Thanks to the high quality of materials used in all components, the Wilo-Actun ZETOS is able to pump acidic and alkaline water or water with a high salt content. This again demonstrates the universal applicability of our borehole pump..

4 - Field of application: Professional irrigation/agriculture

Challenge: In many areas with a low groundwater level, water needs to be pumped from deep below ground to meet the requirements of professional agriculture. Solution: Borehole pumps ensure that the required supply is met. The Wilo-Actun ZETOS is a robust pump with a long service life – even in locations with a high sand content. On top of that, it can overcome delivery heads of up to 640 metres.

5 - Field of application: Industry/offshore

Challenge: from lightly contaminated water to aggressive fluids: The demands on pumps in the industrial sector could hardly be more extreme. Drilling rigs need to pump corrosive salt water; the high sand content of water in the industrial dewatering of mines poses a significant challenge to pumps. Solution:Made of 1.4408 corrosion-resistant stainless steel, the Wilo-Actun ZETOS is more than a match for the challenges of the offshore sector, such as those posed on a drilling rig. And thanks to its EPDM neck rings, it is also highly suitable for pumping water with a sand content of up to 150 g/m3 – as may be encountered in mine dewatering, for example.

“Best in class”

New standards in submersible pumps.

Advantages of the hydraulics

The Wilo-Actun ZETOS stands out thanks to its multistage hydraulics with semi-axial impellers. The housing parts and impellers are made of investment-cast stainless steel. An optimised impeller design with a cast balancing weight ensures smooth operation. The pressure connection can optionally be equipped with an integrated non-return valve.

Technical data for the hydraulics

- Max. volume flow: 385 m3/h

- Max. delivery head: 640 m

- Max. fluid temperature: 70 °C

- Max. sand content: 150 g/m3

- K8 pressure connection: G 5, K10: G 6, DN 150 (PN 10/16), DN 150 (PN 40)

Wilo-Actun ZETOS_Feature_EN

Wilo-Actun ZETOS_Feature_EN

Project

Since 1990, the Bad Überkingen waterworks has supplied around 825 households, numerous agricultural businesses and a golf course with around 268,000 cubic metres of water annually.

Challenge

The elevated tanks are located on the plateau of the Swabian Mountains, meaning that sufficient pressure is required to pump water to a height of 335 metres. And on top of that, it has to be energy-efficient.

Background

After 30 years in operation, the efficiency of the high-pressure multistage centrifugal pump in sectional construction originally installed in the waterworks was steadily decreasing. The old machinery was replaced with two Wilo-Actun ZETOS-K8.50-15 and two Wilo-Sub TWI 6.30 pumps. The pressure shroud pumps now ensure the safe and efficient transport of potable water to the elevated tanks – with a delivery head of up to 335 metres.

Implementation

The compact design of the pump enables a highly space-saving, simple, and therefore cost-effective installation. The submersible pumps are encased in a pressure shroud, allowing the units to be integrated into the existing system using a horizontal dry well installation. Additionally, the Wilo pressure shroud pumps are also overflow-proof.

Result

With an overall efficiency of up to 76 percent, the good hydraulics and built-in permanent magnet motors with speed regulation and control system make energy savings of up to 100,000 kilowatt hours per year possible. The low-maintenance operation also leads to additional cost savings for the operator.

Built-in products

2x Wilo-Actun ZETOS-K8.50-15 + motor NU 711/-4/100 Volume flow Q = 15.3 l/s Delivery head H = 333.9 mWG 2x Wilo-Sub TWI 6.30-35 + motor NU 611T-2/30 Volume flow Q = 5 l/s Delivery head H = 329.3 mWG

Wilo-EFC

- Quick and efficient commissioning thanks to the user-friendly operation assistant.

- High energy efficiency and compact design as a result of up to 98 percent efficiency.

- An economical solution thanks to minimal cooling requirements.

- Comprehensive coverage of pump applications provided by adjustable control modes.

- Flexible connectivity provided by optional connections to various bus systems.

Wilo-EMU 12…24“

- Hydraulics adapted to the duty point enable energy-efficient operation.

- Individually configurable motors and materials for reliable operation in all types of application.

- Drinking water versions with ACS approval.

- Motors with sheath flow cooling (CoolAct technology) for greater power density.

- Rewindable motors with easy maintenance.

- Pressure shroud for application as a pressure-boosting system..

Wilo-Sub TWI

- Long service life thanks to corrosion-resistant stainless steel, optionally in V4A quality.

- Individually configurable motors and materials for reliable operation in all types of application.

- Drinking water versions with ACS approval.

- A high degree of flexibility thanks to 4, 6, 8 and 10-inch versions.

- Volume flow performance from 1 to 250 m3/h.

FAQ

Are the pumps produced entirely by Wilo?

Yes, the pumps are produced at our site in Hof, Germany, and are 100 % tested.Is the 1.4408 stainless steel version suitable for sea water?

Wilo has decades of experience in the offshore sector. Our experiences using the pump in sea water have been positive. A version made of 1.4517 (duplex stainless steel) is also available.Is the Ceram coating approved for drinking water?

The Ceram CT coating conforms to German Federal Environment Agency (UBA) standards and is approved by the French water regulations advisory scheme (ACS).What frequency converter is required to drive the permanent magnet motors?

The Wilo-EFC offers numerous options and we recommend it for use in all applications. However, any frequency converter may be used.Does the power dissipation of the frequency converter cancel out the efficiency benefits of the permanent magnet motor?

The Wilo-EFC’s power dissipation is about two percent. In addition to that, there may be losses caused by the output filter. However, these losses do not come close to neutralising the efficiency benefits of the permanent magnet motor – which are up to 13 percent. That’s on top of excellent performance in the partial load range.Your advantages

SOLID T impeller

- Patented SOLID hydraulics for reduction of clogging susceptibility, suitable for untreated sewage

- High hydraulic efficiency

- Reduction of vibrations through a flow-optimised impeller geometry for secure operation and long service lives

- Energy-efficient IE3 motor technology available as an option

- Ceram coating and special material for protection against abrasion and corrosion

SOLID G impeller

- SOLID hydraulics for reduction of clogging susceptibility, suitable for untreated sewage

- Consistently high efficiency due to adjustable suction port

- Process reliability thanks to optimised impeller geometry for safe pumping of untreated sewage with long-fibre components

- Energy-efficient IE3 motor technology available as an option

Your advantages

- Safeguards your processes. Large bearings of the planetary gear to efficiently absorb the mixing forces.

- Efficient energy usage.The innovative blade geometry ensures the best possible specific thrust coefficient.

- At the same time, this reduces your energy and operating costs.

- Reliable operation.Clogging-free operation with backward-curved incoming flow edge.

Your advantages

- Maximum operational safety with separation of solids from the sewage: Large solids do not have to pass through the pump - no clogging

- Cost-effective thanks to retrofit system for simple renovation of old pumping stations

- Durable and corrosion-free due to the use of PE and PUR material

- Easy maintenance, even during operation – thanks to hygienic dry well installation and easy access from outside and individual blocking

- Future-proof even with increasing solid content in sewage

- Flexible installation in buildings or in chambers from 1,500 mm diameter

- Easy to integrate and ready-for-connection Plug&Pump system

- Energy savings due to efficient submersible sewage pumps optionally with IE3 motors

Wilo-EMUport CORE - Separate and transport solid substances. Clean, safe and reliable.

Growing solid content in sewage is creating great challenges in the context of drainage of entire localities, but also public buildings such as hotels and airports hospitals. The technological and economical solution: Wilo-EMUport CORE. The innovative solids separation system offers the optimum operational reliability and guarantees reliable transport of sewage.Future-proof installation.

The solids separation system proves to be a future-proof system solution thanks to the separation of solids from the sewage. The product also ensures reliable operation with an increasing solid content. Due to the use of durable and corrosion-free polyethylene and polyurethane materials, there is no risk of pitting and crevice corrosion.

Clogging-free

Sewage pump failures are frequently caused by coarse solid material. The solids separation system from Wilo separates this material in the sewage, which means that large solids no longer have to pass through the pump. Maximum operational reliability and efficiency are combined in the system to ensure trouble-free operation. The fully submersible system (IP68) continues to run smoothly even in the event of water ingress.

Efficient

Wilo solids separation systems are characterised by their extremely easy maintenance. Thanks to the hygienic dry well installation, the system components only come into contact with the fluid internally. Easy and convenient accessibility is thereby ensured for maintenance work. The transparent inlet box cover enables a simple visual inspection of the system. Quick-release connectors on the cleaning opening as well as the pump connections save both time and money during maintenance procedures.

Wilo-EMUport CORE_Feature_1_EN

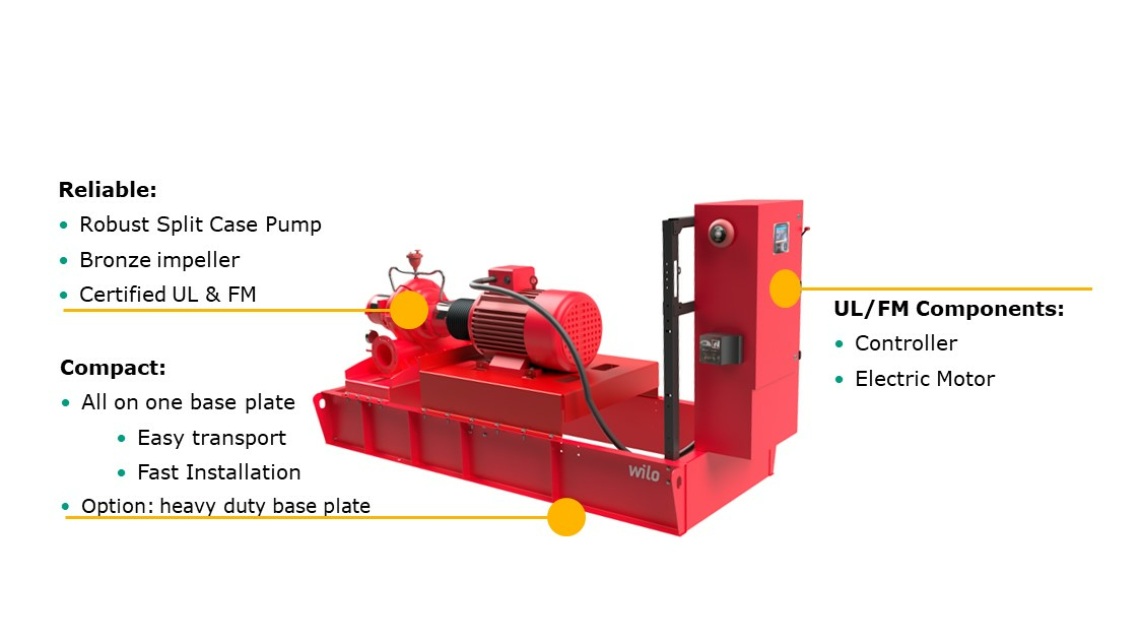

Your advantages

• Certified, modular pump set according to NFPA standards for the highest level of design flexibility

• Robust pumps with axially split housing up to 2500 gpm and 260 psi for a wide field of application and long service life

• Compact design on a universal baseplate for easy transport, installation and maintenance

• Power reserve for a high level of safety

• Modularity enables a configuration tailored to individual requirements

Your advantages

- Multistage, speed-configurable stainless steel high-efficiency pump with 2D/3D hydraulics and standard motor

- Optimised design for easy operation, transportation and installation with handles, lantern adjustment and rotatable free flanges

- User-friendly display with Green Button Technology and full text menu

- IF plug-in module for quick communication with the BMS

- Quick maintenance due to innovative cartridge mechanical seal and spacers

- Lower life cycle costs due to new Helix design

Your advantages

- Easy handling due to its light weight, perfect for continuous operation

- Brass impeller for fluids up to 60 °C

- Efficiently thanks to low power consumption with maximum delivery head and maximum volume flow

- Up to 7 m negative suction head

- Expandable with electronic control of pumps Wilo-HiControl 1

Your advantages

- User-friendly thanks to its low weight and compact dimensions

- High supply guarantee due to good hydraulic output, self-priming up to 7 m, even at low flow

- Heavy-duty design for long-lasting operation

Your advantages

- User-friendly thanks to its low weight and compact dimensions

- High supply guarantee due to good hydraulic output, self-priming up to 7 m, even at low flow

- Heavy-duty design for long-lasting operation

Your advantages

- High reliability in abrasive fluids thanks to rubber-coated hydraulics and an impeller made of Duplex chrome steel

- Easy installation thanks to low weight and flexible pressure connection (vertical/horizontal)

- Active cooling for reliable continuous operation

- Continuous duty in slurping operation thanks to passive cooling

- Easy maintenance thanks to quick access to wearing parts

- Equipped with energy-efficient IE3 motor technology as standard

- Highest operational reliability thanks to integrated protection function

Your advantages

- Dry-running protection for high operational safety

- High reliability thanks to automatic operation and corrosion protection through coated hydraulics

- Standardised design for easy installation

- Compact design and quiet running (55 dbA) for domestic use

- Low power consumption thanks to automatic control

Your advantages

- Easy installation thanks to ready-to-plug and compact design

- Extremely low-noise (45 dbA) and thanks to its drinking water certification it can be used in a residential environment

- Safe operation due to numerous integrated protective functions

- Lower energy consumption thanks to automatic regulation

- User-friendly operating panel with control lamps

Your advantages

- Maximum operational reliability and reduced service costs, especially for pumping untreated sewage, thanks to self-cleaning properties

- Lower energy costs thanks to high hydraulic efficiency and up to IE5 motor technology in wet and dry well installation (based on IEC TS 60034-30-2)

- Corrosion protection provided by an optional Ceram coating for a long service life in aggressive media

- An optional Digital Data Interface (DDI) with integrated vibration monitoring, data logger, web server and digital rating plate for convenient monitoring and system integration

- Nexos Intelligence can be integrated for pump and system optimisation

This is Water 4.0

- Water 4.0 is the key word that sums up intelligent, connected systems as the fourth level of the water sector revolution.

- Water 4.0 is putting the spotlight on digitalisation and automation

- Objective: Enabling a future-proof water infrastructure with the environment and water circuit through connecting water users with components

- High transparency for water users, meeting current needs

That’s why Wilo-Rexa SOLID-Q is Water 4.0

- Connectivity and the transfer and analysis of data are key elements of Water 4.0.

- In the sewage pump station, reliability, efficiency and convenient connectivity are currently the main focus.

- The integrated Nexos Intelligence takes account of digitalisation and automation by recognising clogging and starting rinsing cycles automatically.

- The Wilo-Rexa SOLID-Q with Nexos Intelligence combines the latest developments in hydraulics, motor technology and electrics with intelligent control software.

- It is characterised by operational reliability, energy efficiency and the highest level of digital networking.

- Connecting with the communication network via in-built Ethernet interface with standard network protocols and control through integrated web servers.

- Remote monitoring and documentation of pumps, maintenance and sensor data through the Digital Data Interface.

- It can manage a pumping station with up to four pumps independently in a master/slave arrangement and includes an automatic mode for reducing pipe friction losses and energy-optimised control.

- With the Ethernet interface, installed in the pump for the very first time, the system can communicate with other components of the smart sewage pump station and pass on the data for further analysis to a control system or cloud.